Safety & Health

Safe Workplace, Healthier employees

Establishment of Safety Management System

Kia is building a safety management system based on ISO 45001, using the principles and policies of safety and environment as its foundation. With the goal of establishing autonomous safety management, we have set the Safety and Environment Vision 2025 Roadmap to achieve a safety and environment system at the level of ‘voluntary participation.’ Accordingly, we are promoting improvement activities.

Mission

By putting people and the environment first, we strive to create a culture of safety and make it a part of out daily lives.

Vision

Integrate the safety and environment systems of all our facilities across the globe and achieve Safety Level 4 by 2025.

Safety and environment management system

Proactive regulatory compliance

Meet global requirements and minimize regulatory risks

Inherent safety design

Ensure perfect safety from the design stage

Minimize environmental pollutant emissions

Actively adopt energy-saving and eco-friendly technologies

Internalize safety consciousness

Promote a culture of complaance and establish a safety education system

Basic Principles

Mid- to Long-Term Directions for Ensuring Security

| Year | ~2020 | 2021~2022 | 2023~2024 | 2025~ *New Targets To Be Set After 2026 |

|---|---|---|---|---|

| Target | Safety leadership | Manager-led safety management | On-site participatory safety management | Establishment of autonomous safety management |

| Culture |

|

|

|

|

| System |

|

|

|

|

| Workspace Environment |

|

|

|

|

Safety and Environment Policy

1. Compliance with laws and regulations related to the safe environment

We have a safe environment system that meets global requirements, comply laws and regulations, and prioritize the requirements of stakeholders.

2. Minimization of the risks of the safety environment

We build a safe and pleasant work environment where our employees can create the value of their work and provide a happy experience to customers.

3. Minimization of environmental pollutant emissions

We optimize energy and resource input in all production areas, and actively introduce ecofriendly technologies to minimize emission of environmental pollutants.

4. Organizational culture in which safety is internalized

We strive to create a safety culture in which employees discover threats and proactively address those threats in order to create a safer workplace.

Kia Safety and Environment management system

Kia prevents industrial accidents by providing a safe and pleasant work environment and spreading a safety culture, and improves the health of its and its partners' employees to fulfill its corporate social responsibility. We realize safety and health sustainable management by establishing an autonomous safety management system based on the safety and health management system (ISO) with the support of the safety and health leadership of the top management.

Industrial Accidents

| 2022 | 2023 | 2024 | |

|---|---|---|---|

| No. of industrial accidents | 388 | 457 | 381 |

| Industrial accident rate(%) | 0.77 | 0.89 | 0.75 |

Lost Time Injury Frequency Rate(LTIFR*)

| Classification | 2022 | 2023 | 2024 |

|---|---|---|---|

| Employees | 1.71 | 1.82 | 1.36 |

| Suppliers' employees | 16.53 | 10.76 | 14.59 |

* LTIFR : Loss of work accident rate, and the formula is as follows: Number of injuries (accidents) in a 12-month period / Total hours worked by all employees in the same 12-month period x 1,000,00

Occupational Injury Frequency Rate(OIFR*)

| Classification | 2022 | 2023 | 2024 |

|---|---|---|---|

| Employees | 2.15 | 2.65 | 2.40 |

* OIFR : Loss of disease-related accident rate, and the formula is as follows: Number of injuries (accidents) in a 12-month period / Total hours worked by all employees in the same 12-month period x 1,000,00

Serious Accident Prevention

Critical Accident Reporting System*

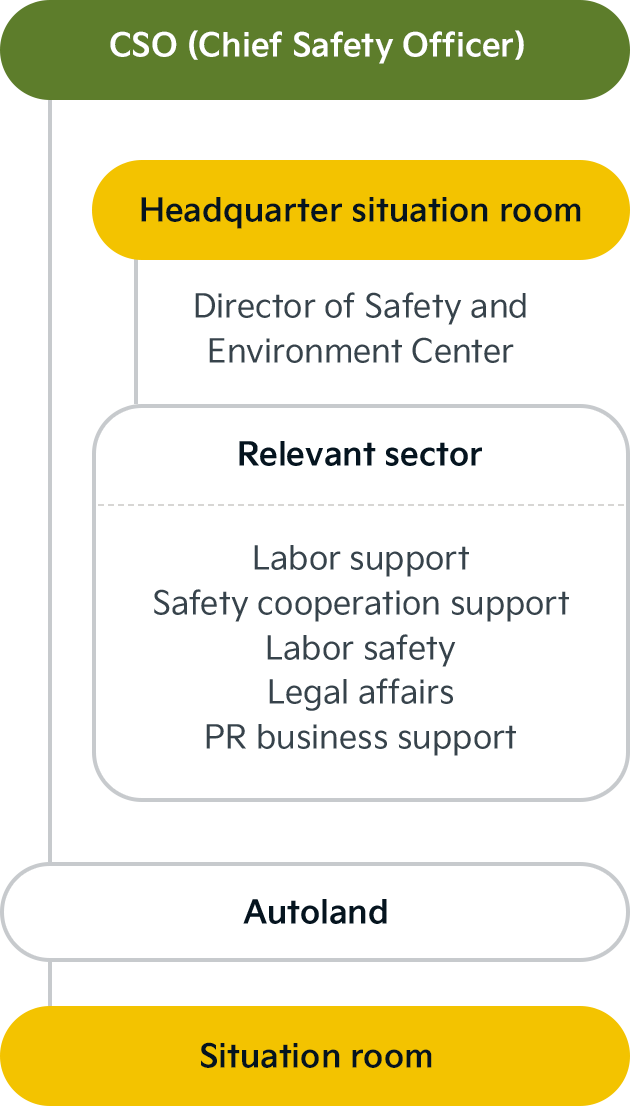

CSO (Chief Safety Officer)

Headquarter situation room: Director of Safety and Environment CenterRelevant sector: Labor support, Safety cooperation support, Labor safety, Legal affairs, PR business support

Autoland Situation room

* Autoland

Main Task

- Initial Response - Suspension of work, evacuation of workers, measures to prevent further damage

- Accident investigation and accident report (internal/external)

- Patient status identification and relief measures

Critical Accident Prevention System

- Regular operation of company-wide safety review meetings led by the Chief Safety Officer (CSO)

- Sharing and supporting SIF discovery and improvements 3 times a month - Creation of a Serious Accident Prevention Team

- Inspection and report on the implementation of the Serious Accident Punishment Act

- Review of safety and health compliance and reporting to the CSO once semiannually - Activation of Serious Accident Contingency Plan and conducting regular drills (once semiannually), etc.